Press Tool Maintenance is extremely important to our operations. Press tools are essential pieces of equipment in many industries, including automotive, aerospace and electronics. These tools are responsible for producing high-quality metal pressings which are critical to the functioning of the products they are used in. However, press tools are also prone to wear and tear, which can lead to production downtime, reduced quality, and safety risks.

Here we look in more detail at the importance of press tool maintenance in the presswork manufacturing process:

Improving Efficiency

Press tools require regular maintenance to ensure that they function at their optimum level. This includes cleaning, lubricating, and replacing worn out parts. When the tool is well-maintained, it also runs smoothly and increases efficiency.

Reducing Downtime

Downtime is a costly issue for any production facility. It can result in lost revenue, missed deadlines, and increased costs. Proper press tool maintenance however, helps to prevent breakdowns and malfunctions, reducing downtime and keeping production on schedule.

Ensuring Safety

A poorly maintained press tool can be dangerous to operators and other personnel in the area. Regular maintenance also helps to identify and correct safety hazards, reducing the risk of accidents and injuries.

Maintaining Quality

Press tools are responsible for producing high-quality components. However, if the tool is not well-maintained, it can produce metal pressings which are out of tolerance or have other defects. Moreover, regular maintenance helps to ensure that the tool is producing parts to the required specifications, maintaining the quality of the final product.

Extending Tool Life

Press tools are expensive pieces of equipment, and replacing them can be a significant expense. However, regular maintenance helps to extend the life of the tool, reducing the need for costly replacements.

Conclusion

So, regular and effective maintenance is essential to ensure the efficient and safe operation of press tools. Regular maintenance can help to reduce downtime, improve efficiency, maintain quality, and extend the life of the tool. Therefore, by choosing a supplier which prioritises maintenance, customers can ensure that their press tools are operating at the optimal level, which can lead to increased productivity and cost savings.

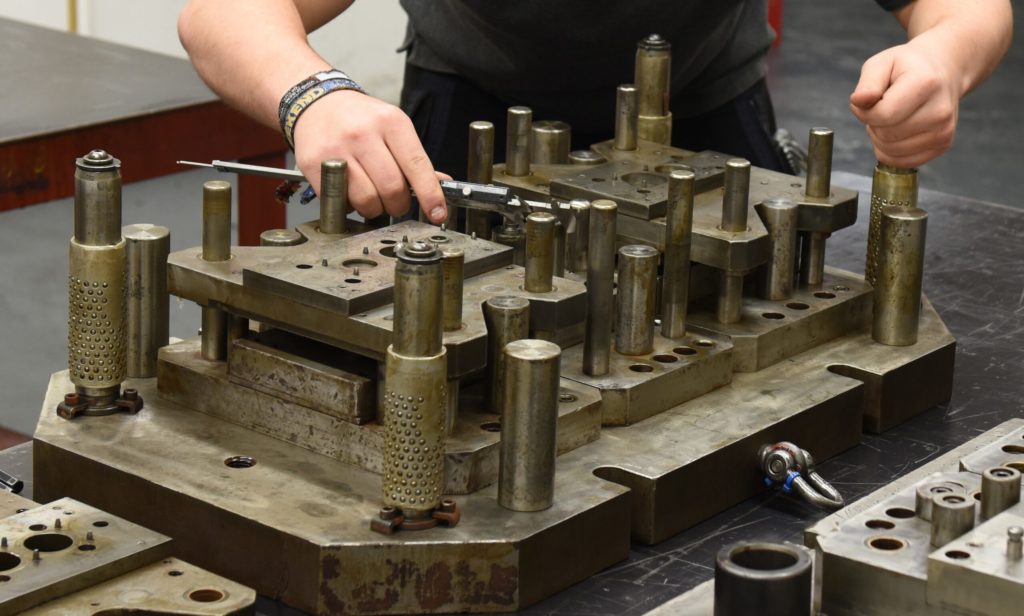

At Brigham, our team of in-house tooling engineers are dedicated to ensuring efficient production, consistent quality, functionality and value in all of our metal pressings. Our fully equipped tool room is integral to our main manufacturing site, enabling us to quickly troubleshoot problems and ensure pressing continuity and quality. All presswork tooling is maintained by our team throughout its useful life.